TM 5-4240-5501-148P

STARTERS

Starter Generator 12V

12 VOLT ELECTRIC

STARTER-GENERATOR UNIT

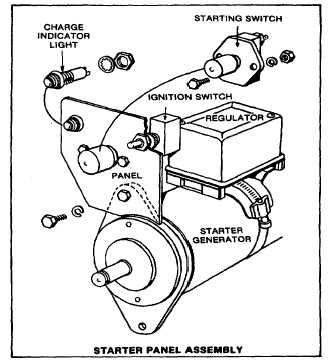

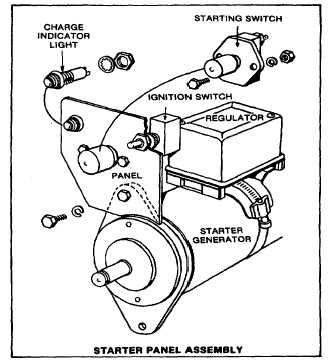

Fig. 130 - Starter Panel Assembly

Removing and Replacing Belts

Remove belt guard. Loosen starter-generator unit

mounting bolts and push the unit toward the engine as

far as it will go. The belt (s) can then be removed.

(Note: Starter-generator units on some models are

equipped with two belts. On these units, both belts

should be replaced even though only one belt appears to

be worn. Use only matched sets of belts.) Do not force

belts onto pulleys. There is sufficient adjustment to allow

them to be slipped in place. After belt has been installed

apply a 30 lb. (13.6 kg) force to the upper pulley and

flange.

Tighten mounting bolts securely and replace belt guard.

NOTE: Belts are of special high strength design. See

Figs. 134 and 135 on page 43. Use only genuine factory

replacements obtainable at authorized Briggs & Stratton

service station.

Emergency Winter Operation

If run-down batteries are repeatedly experienced due to

short or infrequent operation at low temperatures, it is

advisable to temporarily increase the generator charge

rate.

A simple method of increasing the charge rate is to

disconnect the lead to the regulator BAT terminal and

reconnect this lead to the regular (L) terminal. This

bypasses the current-voltage feature of the regulator

automatically increasing the amount of charge to the

battery. See Fig. 132.

CAUTION

: Operate the regulator with these connected during cold

weather when operating periods are short or infrequent.

Re-establish the original lead connections as soon as

mild weather returns or operating time becomes normal:

otherwise the battery will be damaged by over charging.

Battery Size

A 12 volt battery of 50 ampere hour capacity is

recommended. CAUTION: Battery must have negative

(-) terminal grounded to engine or machine frame.

Maintenance of Battery and Cables (See Fig. 131 for

cable size)

Check electrolyte level every 100 hours. Maintain level

with distilled or demineralized water. Avoid overfilling.

Keep top of battery clean by periodically washing with a

brush dipped in ammonia or bicarbonate of soda solution

followed by flushing with clean water. Keep battery hold

down clamps tight to prevent vibration of battery, but do

not overtighten as this may warp case.

Battery cable clamps must be kept tight on terminals to

provide a good contact. If corrosion occurs at terminals,

disconnect cables and clean clamps and terminals

separately. Coat clamps with petroleum jelly and re-

install.

Warranty and Service

For warranty and service on all Delco-Remy parts,

contact United Motors Service Agencies.

39