TM 5-4240-5501-148P

STARTERS

Gear Drive 12V & 120V

DISASSEMBLY OF STARTER MOTORS

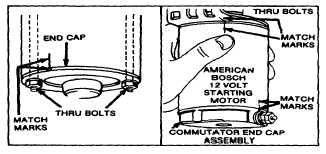

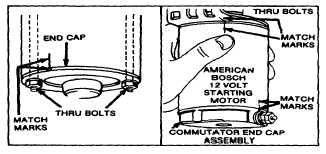

Remove the lockwasher, nuts and thru bolts. See Fig.

116. The armature, drive cap and gear drive can now be

removed as an assembly.

NOTE: THRU BOLTS AND NUTS MUST BE PLACED

IN THE SAME POSITION AS WHEN REMOVED OR

INTERFERENCE MAY RESULT.

(See checking starter motor drive if repair, cleaning or

replacement of drive assembly is necessary.)

Fig. 116 Removing Thru Bolts

CAUTION: Do not clamp the motor in a vise or strike the

motor with a hammer. Some motors include two

powerful ceramic magnets which can be broken or

cracked if the motor housing is deformed or dented.

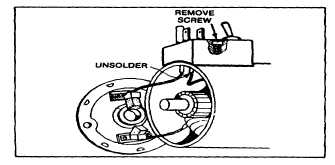

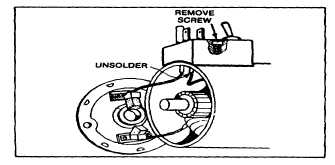

To remove the commutator end cap, lift the brush

springs and slide brushes out of the brush holders. The

120 volt AC starter motor rectifier assembly may now be

removed by loosening the cover screw and unsoldering

the field lead attached to the rectifier assembly. See Fig.

117.

Fig. 117 Removing Rectifier

Clean all dirt or corrosion accumulations from the

armature, commutator end cap, drive end cap, etc. The

bearings, housing and armature should not be soaked in

a cleaning solution. The armature commutator may be

cleaned with a fine sand paper. Do not use emery cloth,

as emery will embed in the commutator and cause rapid

brush wear. If it is suspected that the armature, field coil

or motor housing is defective, new parts should be tried

in the motor. If proper testing equipment is available,

check the suspected armature or field coil to determine if

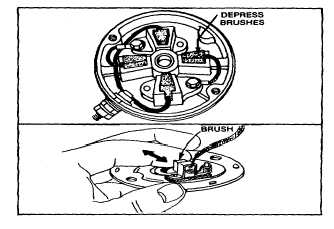

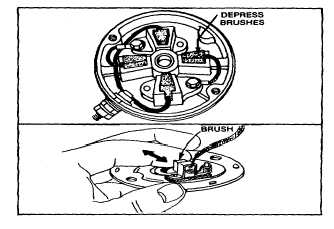

it is defective. The brushes should be checked for

proper seating, weak brush spring, dirt, oil or corrosion.

Brush spring pressure should measure from 4 to 6

ounces when pressed to working position. Also check to

be sure brushes are not sticking in their respective brush

holders. See Fig. 118.

Fig. 118 Checking brushes

CHECKING THE RECTIFIER ASSEMBLY 120 VOLT

AC STARTER MOTOR

The rectifier assembly consists of a spring loaded switch,

which is in a normally "off" position, an AC three wire

ground receptacle and four rectifiers encapsuled in an

epoxy case. The test procedure for checking the rectifier

is as follows:

Equipment Needed

1.

An AC volt meter capable of measuring 120 volts

AC.

2.

A DC volt meter capable of reading 100 volts

DC.

3.

A 10,000 ohm resistor (1 watt).

34