TM 5-4240-501-14&P

STARTERS- Briggs & Stratton

Gear Drive 12V & 120V

Mark the center of the rivets holding the ring gear to

flywheel, with a center punch. Drill out the rivets using a

3/16" (4.8 mm) drill. Clean holes after drilling. Fig. 83.

Attach new gear to flywheel using four screws and lock

nuts provided with gear.

CHECKING STARTER MOTORS

If a starting problem is encountered, check the engine

thoroughly to be sure it is not the cause of starting

difficulty. It is a good practice to remove the spark plug

and rotate the crankshaft by hand, to be sure it rotates

freely. Any belt, clutch or other parasitic load will affect

cranking performance.

Service procedures for both the 12 volt and 120 volt

starter motors are similar and will be covered together,

except where noted otherwise.

A list is provided to aid in diagnosing problems for 120

volt DC and 120 volt AC systems. See page 9 and 10.

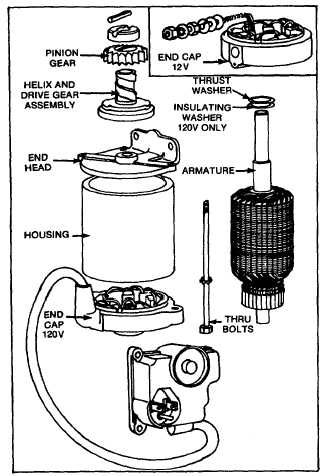

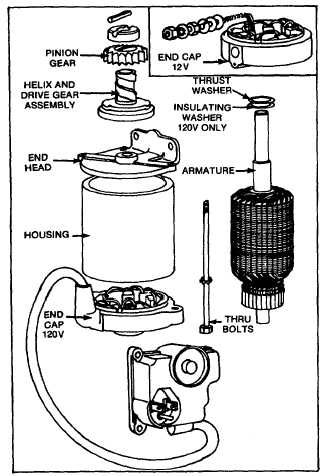

Fig. 84 - 12 Volt & 120 Volt Starter Motor -

Exploded View

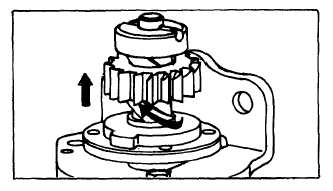

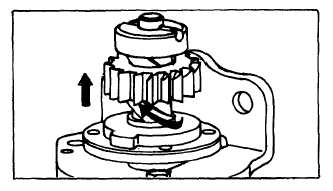

CHECKING STARTER MOTOR DRIVE

When the starter motor is activated, the pinion gear

should rise, engaging the flywheel ring gear and crank

the engine. This action can be observed by removing

the starter shield. If the starter motor drive does not

react properly, inspect the helix and pinion gear for

freeness of operation. If any sticking occurs, this must

be corrected. Proper operation of the starter is

dependent on the pinion freely moving on the helix. See

Fig. 85.

Fig. 85 - Checking Starter Motor Drive

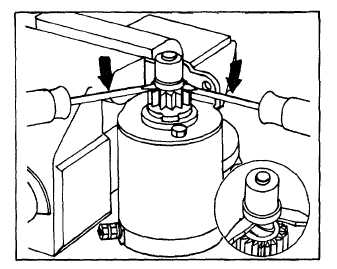

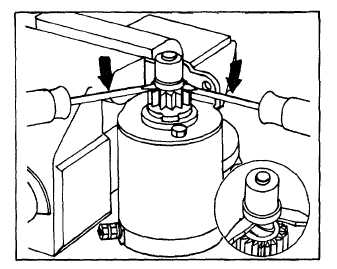

DISASSEMBLING STARTER MOTOR DRIVE

To

remove

the

drive

assembly

for

cleaning

or

replacement, disconnect and remove starter from

engine. Place in "V" block as shown in Fig. 87. Drive

the roll pin out with a hammer and 1/8" (3.2 mm)

diameter punch to remove the retainer.

NOTE: Some starter drive assemblies utilize a gear

return spring. These are protected with a plastic cap

over the drive assembly. Carefully snap the plastic cap

from the cup using two screwdrivers. See Fig. 86.

Fig. 86 - Removing Cap Assembly (Some Models)

24