ALTERNATOR

Tri-Circuit

TESTING STATOR COILS

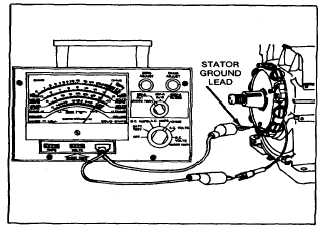

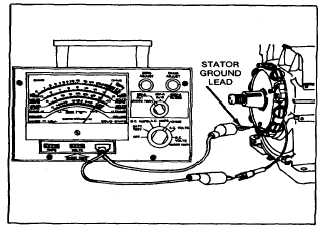

With multimeter, check continuity between ground lead

to stator coil and output connector lead shown in Figure

209. Meter should show continuity. If meter does not

indicate continuity, replace stator.

Fig. 209 - Checking Continuity

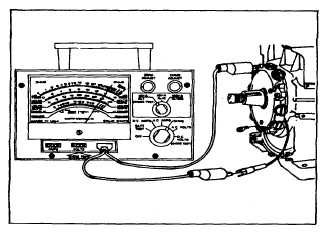

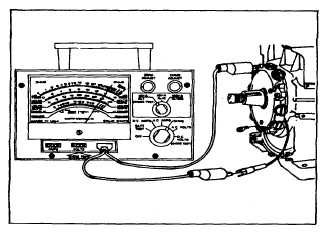

Next, be sure ground lead terminal is not touching a

grounded surface. Check continuity from terminal to

ground. See Fig. 210.

Meter should not show continuity. If meter indicates

continuity, coils are grounded and defective. Examine

lead to be sure the insulation is not -worn or cut. Repair

with tape and shellac if a bad spot is found. If ground still

exists, sator must be replaced.

Fig. 210 - Checking for Grounded Wire in

Stator Assembly

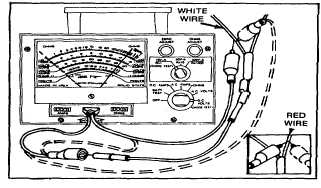

CHECKING DIODES

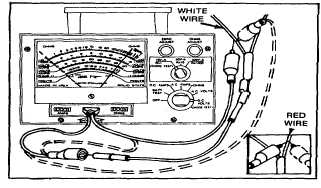

Disconnect charge lead from stator output lead. Using a

multimeter set on resistance scale, check diodes by

attaching one meter lead to connector pin. Touch the

other meter lead to the white wire (light circuit diode),

then reverse meter leads. Meter should show continuity

in one direction only. Repeat this procedure for the red

wire (battery charging diode). Meter should show

continuity in one direction only. If meter shows continuity

in both directions or does not show continuity in either

direction, the diode harness must be replaced. See Fig.

211.

Fig. 211 - Checking Diodes in Wire Harness

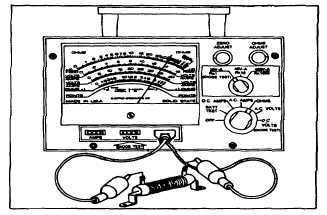

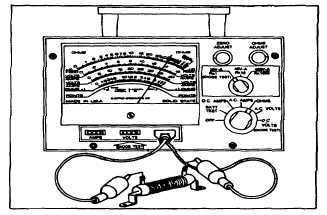

The resistor that reduces battery charging current should

also be checked when testing alternator. See Fig. 212.

An acceptable resistor should have approximately one

ohm resistance. Also check to be certain the double

pole switch is operating properly. See Fig. 207.

Fig. 212 - Checking Resistor and Switch

65