TM 9-2350-256-34-1

CHAPTER 3

REPAIR OF RECOVERY VEHICLE, FULL TRACKED: MEDIUM, M88A1

l

Section 1. REPAIR OF HULL ASSEMBLIES

.

3-1. Description

.

The hull and cab are constructed of cast armor and

armor plate welded into a single unit. Padded seats

are provided in the cab for the crew and passengers.

Doors and hatches are located around the vehicle for

crew access and stowage compartments.

3-2. Seals and Linings

a. General. Repair of the various rubber in-

sulation seals and linings installed on the vehicle

consists of replacing those that are worn.

b. Rubber Sealing Strips on Acetylene Com-

partment Door.

(1) Remove the old seal and discard. Clean the

area thoroughly by scraping off old adhesive and

then removing dirt, grease and other foreign matter

with a wire brush.

(2) Apply fresh rubber base adhesive (NSN

8040-00-281-1972 or NSN 8040-00-843-3461) and

wait until adhesive becomes slightly tacky.

(3) Press new seal (NSN 9390-00-247-2335)

firmly into place and clean any excess adhesive

from surface of seal.

(4) Allow adhesive to thoroughly dry before

closing door.

c. Lining of Fire Extinguisher Bracket Arms.

Refer to TM 9-2350-256-20 for removal and in-

stallation and for repair of the fire extinguisher

bracket assembly. When replacing the lining of the

arm assemblies, use the old lining as a pattern and

cut to the same size. Set the rivet tangs below the

lining surface so that the surface is smooth. Peen

over properly to hold securely in place.

3-3. Pads

a. Rocket Ammunition Storage Box Pads.

Repair of the sponge rubber strips in the am-

munition storage box is the same as for the acetylene

compartment door seals (para. 3-2 b), except that the

new strips are cut to the proper size from sheets. Use

the old strip as a pattern and cut to the same size.

Refer to paragraph 3-2 for repair instructions.

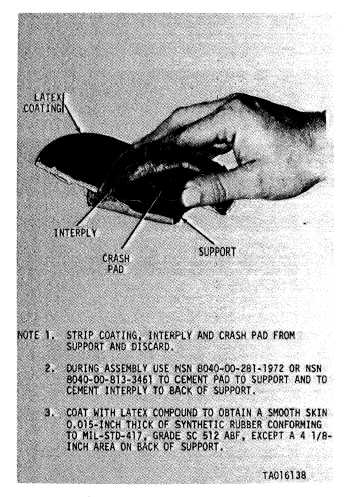

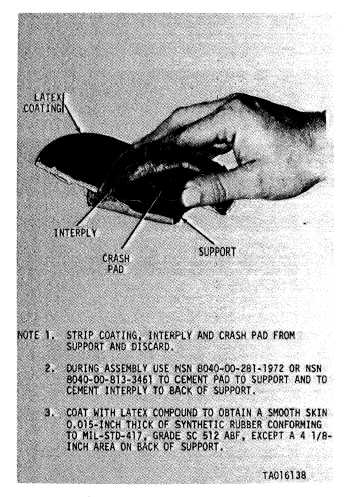

b. Vision Cupola Padding Assembly.

(1) Disassembly. Refer to TM 9-2350-256-20

for removal and installation. Disassemble the vision

cupola padding assembly as shown in figure 3-1.

Figure 3-1. Vision cupola padding assembty–repair.

(2) Cleaning. Scrape dirt and adhesive from the

support and clean with a wire brush. Clean with dry

cleaning solvent or mineral spirits paint thinner and

dry .

(3) Inspection and Repair. Inspect the support

for cracks, distortion, breakage or other damage that

would impair its use. If defective, replace entire

padding assembly.

(4) Assembly. Assemble the vision cupola

padding assembly in reverse order of disassembly.

3-1