TM 9-2350-256-34-1

3-57.

Mechanical

Transmission

Oil

Cooler

Assembly.

a.

Removal.

Refer

to

paragraph

2-33

for

instructions on removal and installation.

b.

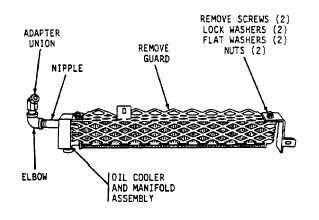

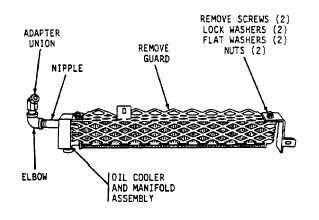

Disassembly. Disassemble the oil

cooler

assembly as shown in figure 3-23.

c.

Cleaning. Clean dirt and other foreign material

from all parts with drycleaning solvent or mineral spirits

paint thinner, followed by wire brushing where necessary.

Dry with compressed air.

d.

Inspection and Repair.

(1)

Inspection.

(a)

Inspect

oil

cooler

for

cracks,

distortion, breakage, and other damage that might cause

leakage or otherwise impair its use.

(b)

Inspect threaded parts for nicks,

cross threading, and other evidence of excessive wear.

(c)

Inspect guard assembly for broken

welds, cracks, and other damage that would impair its

use.

(2)

Repair. Replace any parts that are

defective.

e.

Assembly.

Assemble

the

mechanical

transmission oil cooler assembly in reverse order of

disassembly.

3-58.

Mechanical Transmission and Main Hydraulic

Pump Assembly

a.

Removal. Refer to paragraph 2-32 for removal

and installation instructions.

b.

Repair. Refer to TM 9-2350-256-34-2 for

inspection and repair instructions.

3-59.

Hoist Winch Assembly

a.

Removal. Refer to paragraph 2-35 for removal

and installation instructions.

b.

Repair. Refer to TM 9-2350-256-34-2 for

inspection and repair instructions.

3-60.

Main

and

Hoist

Winch

Brake

Band

Assemblies

a.

Removal. Refer to paragraph 2-39 for removal

and installation instructions.

b.

Disassembly. Disassemble the brake band

assembly as shown in figure 3-24.

Figure 3-23. Mechanical transmission oil cooler

assembly-disassembly and assembly.

c.

Cleaning. Clean dirt and other foreign material

from all parts with drycleaning solvent or mineral spirits

paint thinner, followed by wire brushing where necessary.

Dry with compressed air.

3-44 CHANGE 7