TM 9--2350--292--10

0104 00--2

TRACK TENSION ADJUSTMENT (NEW CONFIGURATION) -- CONTINUED

0104 00

WARNING

Grease will be under pressure. Personnel must wear goggles. Failure to comply

may result in eye injury to personnel.

NOTE

If grease fitting will not take grease or continues to leak grease after one minute, replace

grease fitting.

If pressure relief valve or grease bleed valve works too easily, or if track adjusting link will

not move, notify unit maintenance.

If bronze link overextension indicator is exposed on shaft during adjustment, track adjusting

link is extended too far. Remove one track shoe (WP 0108 00) and restart task.

Removing a shoe from one track does not require removing a shoe from other track.

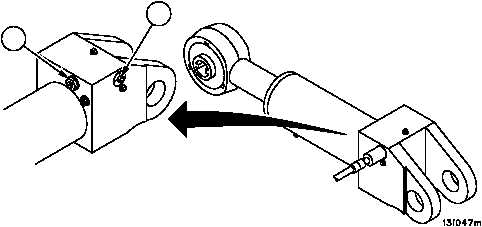

6. Using a grease gun, pump grease into track adjusting link grease fitting (5) until grease spurts out of pressure

relief valve (4).

4

5