TM 9--2350--292--20--1

0099 00--4

BOOM STAYLINE CABLES BECOME SLACK DURING LIVE BOOM

OPERATION OR BOOM CAN BE STOWED WITHOUT ACTIVATING THE

BOOM SAFETY VALVE CONTROL LEVER -- CONTINUED

0099 00

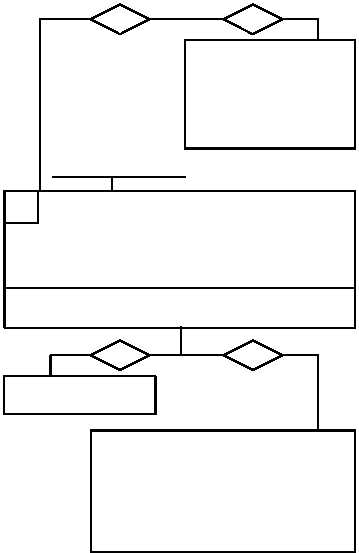

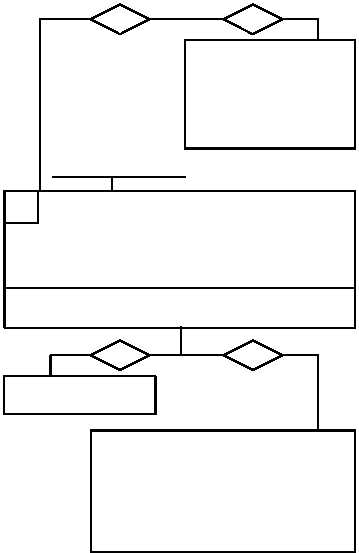

CONTINUED FROM STEP H

T

Are all hoses and components free of leaks, restric-

tions, and damage?

yes

no

If pressure at BSI in

stow range is less than

385 psi, go to Step I. If

pressure at BSI in live

range is greater than 60

psi, notify Direct Support

Maintenance.

yes

no

Tighten leaking connections and remove

restrictions. Verify fault is corrected. If

restrictions cannot be removed from

hoses, replace hoses (WP 0544 00).

Verify fault is corrected. If subplates or

valves are damaged or if restrictions can-

not be removed from them, notify Direct

Support Maintenance.

Notify Direct Support

Maintenance.

FORWARD

CONTINUED FROM

STEP N

8. Shut down hydraulics and main engine

(TM 9--2350--292--10).

1. Remove subfloor plates 10, 11, 12, 15, 18, 23

and 31 (WP 0454 00).

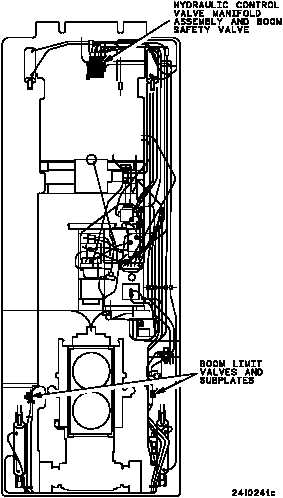

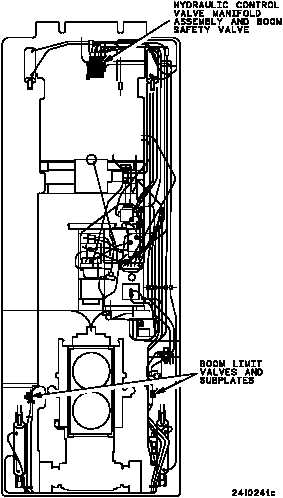

2. Inspect the hydraulic control valve manifold

assembly, boom safety valve, boom limit valve

subplates, boom limit valves and all connecting

hoses for leaks, restrictions, and damage.

Is pressure at boom safety valve ports BSI and BSO 60

psi or less with boom in live range and is pressure at

port BSI 385--470 psi and pressure at port BSO 60 psi

or less with boom in stow range?

U

CONTINUED ON NEXT PAGE