TM 9--2350--292--20--1

0100 00--3

HOIST WINCH FAILS TO OPERATE OR DEVELOP FULL POWER --

CONTINUED

0100 00

CONTINUED FROM STEP E

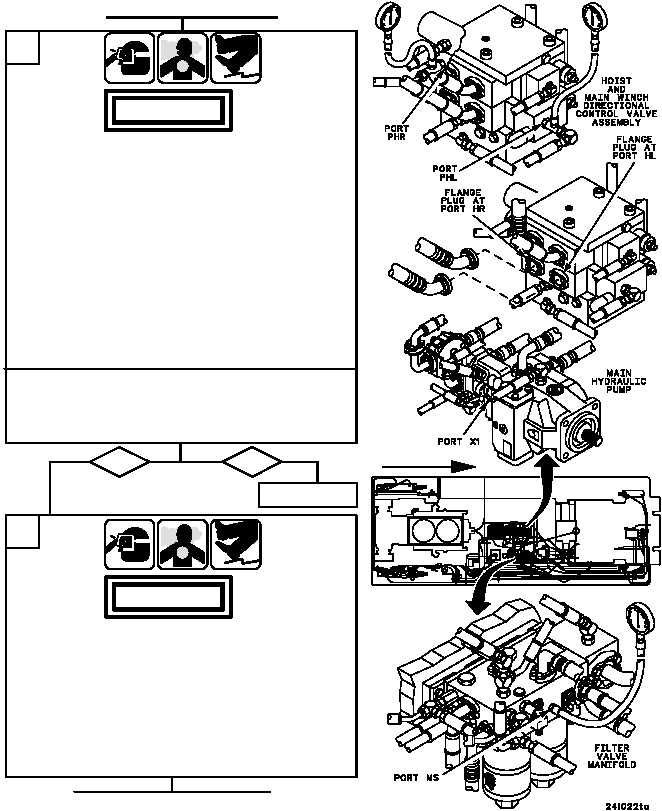

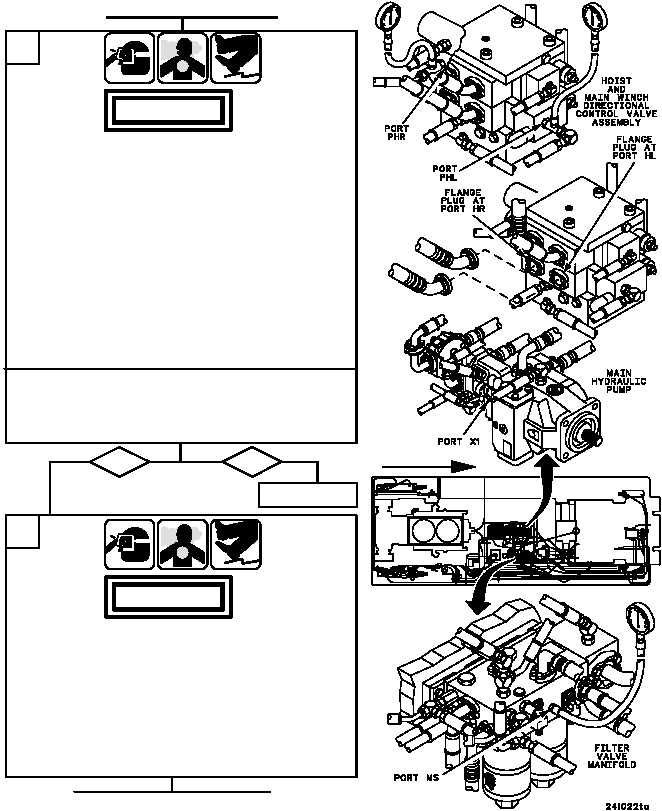

1. Remove hoses from split flanges at ports HR and

HL of hoist and main winch directional control valve

assembly.

2. Install 1--inch flange plugs with o--ring in ports HR

and HL, and secure plugs with split flanges.

3. Install 0--5000 psi dial pressure gauge in the MS

port of the filter valve manifold.

4. Install 0--5000 psi dial pressure gauge with 3/8--inch

tee between port X1 of front pump on main

hydraulic pump assembly and attaching hose.

CONTINUED ON NEXT PAGE

F

When in raise position was pressure at PHR port

385--470 psi, and was pressure at PHL port less than

50 psi; and when in lower position, was pressure at

PHL port 385--470 psi, and was pressure at PHR port

less than 50 psi?

no

yes

1. Install 0--4000 psi testing gauge assembly with

1/4--inch tee between port PHR on hoist and main

winch directional control valve assembly and

attaching hose.

2. Install 0--4000 psi testing gauge assembly with

1/4--inch tee between port PHL on hoist and main

winch directional control valve assembly and

attaching hose.

3. Start main engine, energize hydraulics, and set

engine speed to 1800 rpm (TM 9--2350--292--10).

4. Place hoist control valve lever in lower position and

record gauge pressures.

5. Place hoist control valve lever in raise position and

record gauge pressures.

6. Shut down hydraulics and main engine

(TM 9--2350--292--10).

Go to Step H.

G

FORWARD

WARNING

WARNING