TM 9--2350--292--20--2

0387 00--6

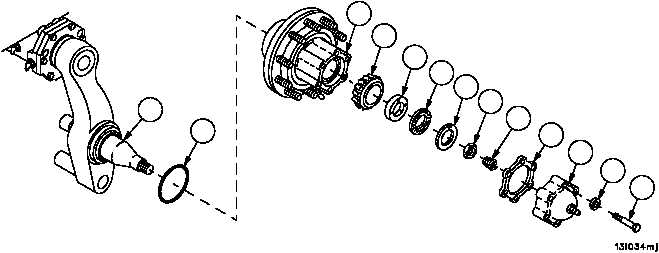

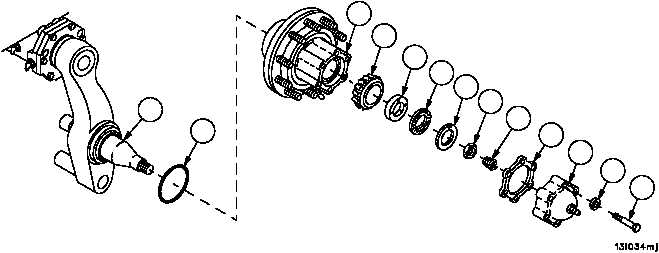

SUSPENSION HUB ASSEMBLY REPAIR -- CONTINUED

0387 00

Installation

1. Recheck position of new preformed packing (13) and install hub assembly (6) on suspension arm assembly (10).

2. Install outer bearing (12) and adjusting nut (11) on suspension arm assembly (10).

3. Torque adjusting nut (11) to 35--40 lb--ft (48--54 N•m) (item 2, WP 0717 00) while rotating hub assembly (6) in

both clockwise and counterclockwise directions.

4. Recheck torque adjusting nut (11) to 35--40 lb--ft (48--54 N•m) (item 2, WP 0717 00) to insure bearings have

seated.

5. Loosen adjusting nut (11), torque adjusting nut (11) to 45--50 lb--in. (5.1--5.7 NSm) (item 2, WP 0717 00). No end

play should be present. If end play is present, repeat installation steps 3 through 5.

6. Install flat washer (9), bearing nut lock (7) and bearing nut (8) on suspension arm assembly (10). Reverse flat

washer (9) if necessary to index pin.

CAUTION

Improper torque could affect the bearing adjustment and

cause equipment damage.

7. Torque nut (8) to 120--125 lb--ft (162.12--169 NSm) (item 2, WP 0717 00).

8. Bend one end of bearing nut lock (7) over flat of nut (8).

9. Install spring (5), new gasket (4) and access cover (3) to hub assembly (6) with six screws (1) and six new lock-

washers (2).

Figure 179

6

12

11

9

7

8

5

4

3

2

1

10

13