TM 9-2350-238-10

TRACK–CONTINUED

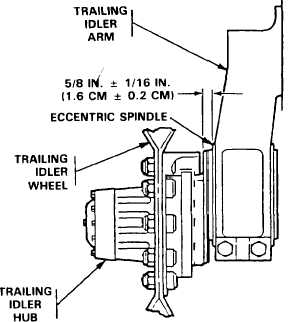

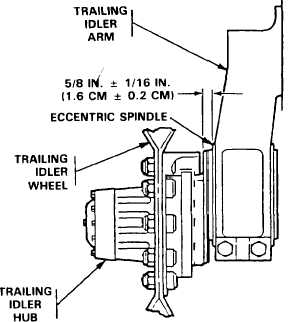

SPINDLE AND IDLER ARM CLEARANCE

Make sure placement of spindle is correct.

Proper placement of spindle in arm is when

approximately 5/8 in. (1.6 cm) of threaded

portion of spindle extends outside of arm, If

placement is incorrect, rotate spindle either in

or out to achieve proper clearance as follows:

1 Decrease track tension.

3-46, steps 1 thru 4.

2 Adjust left side spindle:

Refer to page

a.

Insert 10 in. (25.4 cm) of bar (item

5, appx B) through hub flange into

eccentric shaft spindle.

b. TO increase clearance to 5/8 in, (1.6

cm), drive vehicle forward until spin-

dle has rotated 360 degrees.

Measure clearance. Repeat pro-

cedure, if necessary. To decrease

clearance, drive vehicle rearward.

3 Adjust right side spindle:

a.

Insert 10 in. (25.4 cm) of bar (item

5, appx B) through hub flange into

eccentric shaft spindle.

TRACK REMOVAL AND INSTALLATION

1 Drive vehicle on level ground and posi-

tion track shoe to be removed midway

between bottom of drive sprocket and

first road wheel.

b. To increase clearance to 5/8 in. (1.6

cm), drive vehicle rearward until

spindle has rotated 360 degrees.

Measure clearance. Repeat pro-

cedure, if necessary. To decrease

clearance, drive vehicle forward.

3 Block opposite track to prevent vehicle

movement. Do not lock vehicle brakes.

2 Decrease track tension. Refer to page

3-46.

3-48