TM 9-2350-238-10

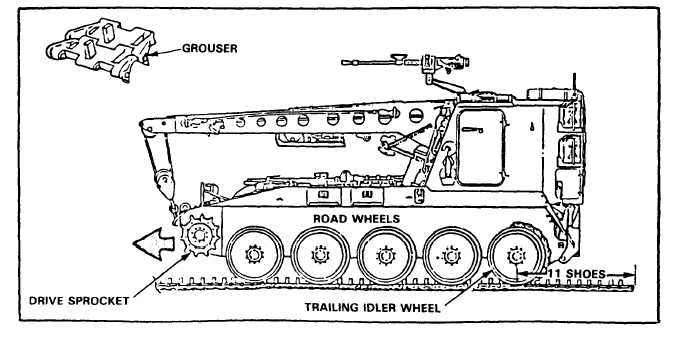

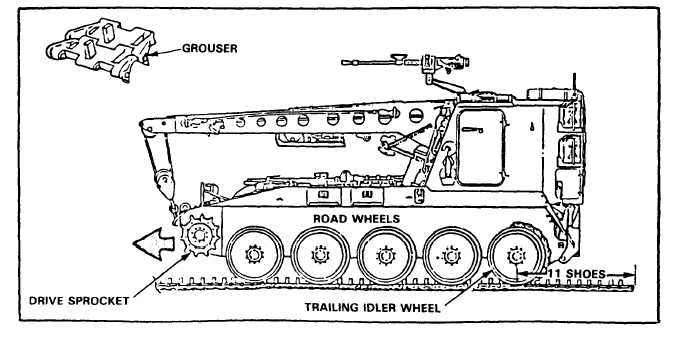

TRACK–CONTINUED

INSTALLING TRACK

1 Lay track out in front of vehicle in a

6 Using drive sprocket, bring both ends of

straight line, directly ahead of and

track together.

touching first road wheel. Position track

on ground with shoe grousers facing

forward.

2 Start engine and drive slowly onto track

to a point where 11 track shoes extend

past centerline of trailing idler wheel.

3 Stop engine; leave parking brake off.

4 Place drift pin in track shoe hole on last

shoe at rear of vehicle. Lift end of track

over trailing idler wheel,

5 Start engine and move vehicle forward

slowly allowing track to rest on road

wheels, lifting up on end of track preven-

ting end from getting caught between

road wheels. When track reaches drive

sprocket, pry or lift track over sprocket.

7 Install two track connecting fixtures

across track shoes to be connected and

tighten equally until holes in ends of

track are aligned. Connect shoes with

track shoe track pin and install self-

Iocking nut.

8 Tighten two nuts on track shoe track

pin. Remove track connecting fixtures,

As soon as possible, have unit

maintenance personnel torque nuts to

160-200 ft-lb (216-270 N-m).

9 Increase track tension. Refer to page

3-47.

3-50