TM 9-2350-238-10

AIR FILTERS–CONTINUED

FILTER BAG CLEANING–CONTINUED

Always wear protective goggles

and stand upwind of blast when

using compressed air.

2 Use compressed air to remove dust from

filter. Insert hose nozzle into each pocket

and blow dust out. A maximum line

pressure of 100 psi (690 kPa) and a 1/8

in. (0.3 cm) internal diameter nozzle are

recommended for cleaning with com-

pressed air.

WET AIR FILTERS AND HULL COMPARTMENT

The following procedures should be followed

if air filters and hull compartment become wet

from fording or washing of vehicle.

1 Remove air filters by following the pro-

cedure on page 3-42.

Do not use steam to clean filter

bag. Maximum temperature

must not exceed 212°F

(100°C).

2 Wash filters with hot or cold water or

water and a nonsudsing detergent.

INSTALLATION

Incorrect installation can cause

misalignment of rubber cap and

damage to filter basket and ac-

cess door latch.

Do not use steam to clean filter

bag. Maximum temperature

must not exceed 212 ‘F

(1OO°C).

3 Wash filter with hot or cold water or

water and a nonsudsing detergent. Hang

filter bag to dry with rubber cap end in a

horizontal position.

3 Hang filter bag to dry with rubber cap

end of bag in a horizontal position.

4 Clean and dry air filter hull compartment

with clean rags and low pressure com-

pressed air.

5 Check air filter access door seals for

nicks or tears. Report any damage to

unit maintenance personnel.

6 Install air filters using following

procedure.

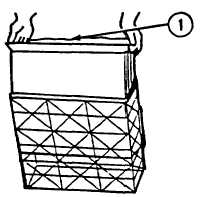

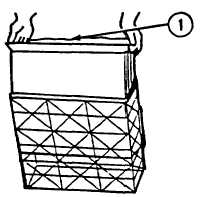

1 Install air filter bag (1 ) in basket and fit

filter bag rubber cap firmly around rim of

basket.

3-44