TM 9-2350-238-34-2

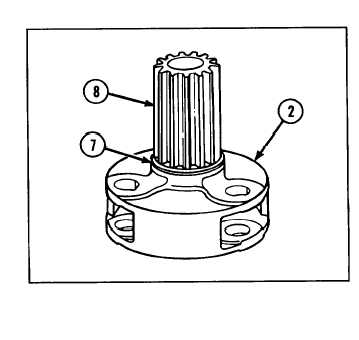

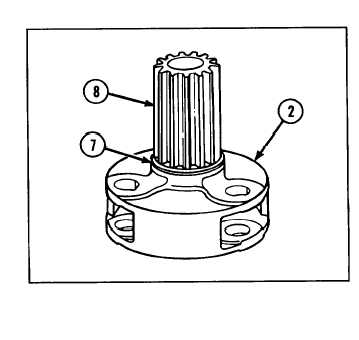

6 If necessary, grind welds securing retain-

ing stop ring (7) to carrier (2), and remove

spur gear (8) and retaining stop ring.

1 Inspect for broken, damaged, or missing parts.

2 If carrier is broken, damaged, or missing, repair is by replacement of next higher assembly.

3 If any kit component is damaged, replace entire hydraulic parts kit.

4 Repair is by replacement of authorized parts (TM 9-2350-238-24P-2).

REASSEMBLY

NOTE

If retaining stop ring and spur gear

were removed, new welds are

necessary during reassembly.

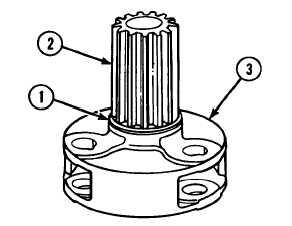

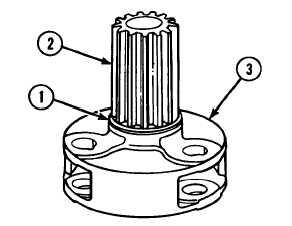

1 If removed, install new retaining stop ring

(1) in groove in spur gear (2).

2 Insert spur gear (2) into carrier (3), seating

retaining stop ring (1 ) firmly against

carrier.

Weld retaining stop ring to carrier.

Do not weld to spur gear.

3 Weld retaining stop ring (1) to carrier (3)

with 0.12-in. (0.30-cm) fillet welds. Weld

three 1.00-in. (2.54-cm) spots placed an

equal distance apart around circle of re-

taining stop ring (1). Weld per MIL-

STD-1261C (MR).

2-79