TM 9--2350--292--20--2

0505 00--2

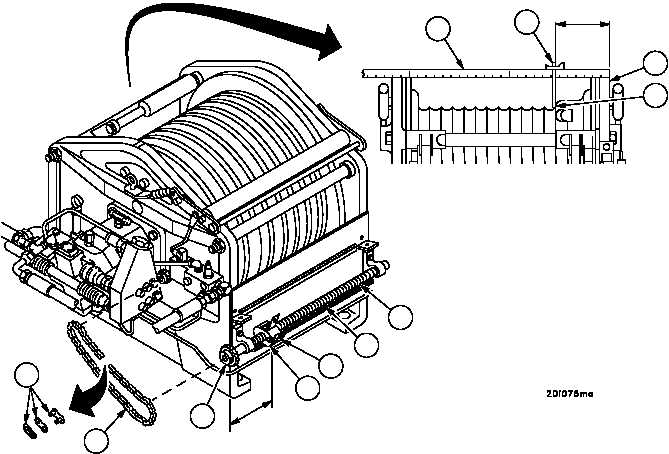

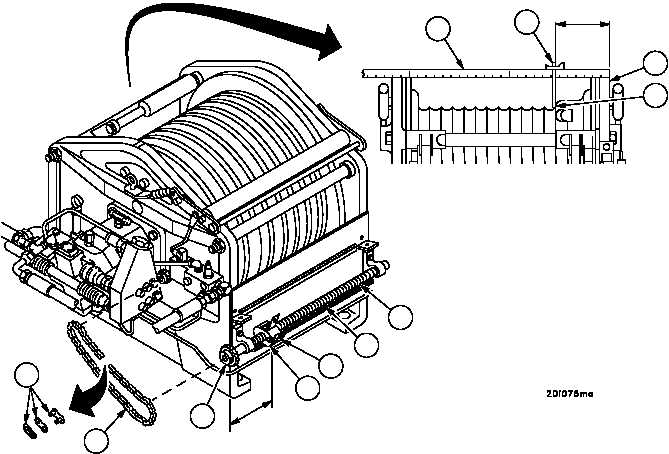

MAIN WINCH DRUM AND DIAMOND SCREW SYNCHRONIZATION

ADJUSTMENT -- CONTINUED

0505 00

Adjustment--Continued

2. Using a steel rule (5) and combination square (6), measure at top of winch, the distance from outside of motor

end winch housing (4) to offset in drum (7). Offset occurs at beginning of rope grooves.

3. Subtract 1.75 inches (44.45 mm) from distance determined in step 2.

4. Check that follower nut (8) is moving away from motor end of winch housing (4) and follower nut trailing edge (9)

is located at distance determined in step 3 (measurement is taken from outside edge of motor end of winch hous-

ing).

NOTE

If measurement in step 4 is not correct, perform steps 5

through 7.

Place rag under roller chain so master link doesn’t drop

down under main winch where it cannot be retrieved.

5. Remove master link (10) in roller chain (11) and remove roller chain.

6. Rotate diamond screw sprocket (12) counterclockwise, when viewed from drive sprocket end (motor end), until

trailing edge of follower nut (9) is at distance determined in step 3.

7. Check that follower nut (8) is riding in groove on the lower edge of nut guard (13) and space between diamond

screw (14) and nut guard (13) is even throughout its full range of travel.

Figure 262

STEP 3

5

6

4

7

10

11

8

13

14

12

9

STEP 4