TM 9--2350--292--20--2

MAIN WINCH AND CABLE GUIDE SYNCHRONIZATION ADJUSTMENT --

CONTINUED

0506 00

Adjustment--Continued

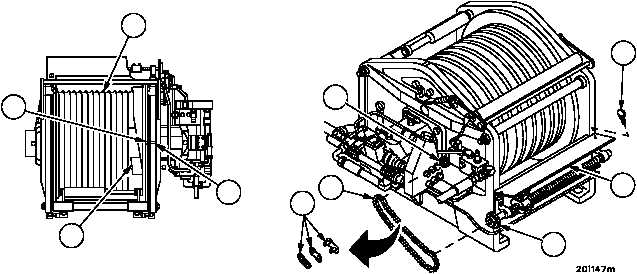

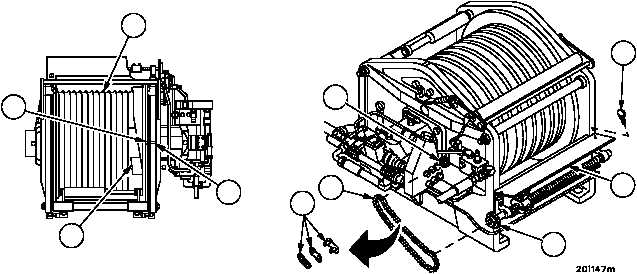

8. Rotate drum (13) until cable pocket (14) is in horizontal (top) position and timing marks on drum flange (1) and

motor end winch housing (2) align.

NOTE

Place rag under roller chain so master link does not drop

down under main winch where it cannot be retrieved.

9. Install roller chain (15) on sprockets (16 and 17). Rotate sprocket (16) the minimum amount possible to achieve

chain (15) assembly. Maximum movement allowed is less than one tooth. Install master link (18).

NOTE

If main winch, upper plate guide or cable guide is re-

moved, replaced or repaired repeat steps 1 through 6.

10. Remove main winch ground hop kit (WP 0498 00).

11. Close nutguard (19) cover and secure with two thumbscrews (20).

Figure 262

1

2

13

14

18

15

20

19

17

16

NOTE

FOLLOW--ON MAINTENANCE:

Install level winder guard (WP 0507 00)

Install main winch wire rope assembly (WP 0499 00)

END OF TASK

0506 00--3/4 blank