TM 9-2350-256-20

CHAPTER12:

MAINTENANCE OF MAlN HYDRAULIC SYSTEM

12 - 5 REPLACE/REPAIR HYDRAULIC SYSTEM OIL FILTER - CONTINUED

a. REMOVAL

NOTE

It is not necessary to remove oil filter

housing to service filter element

assembly (1).

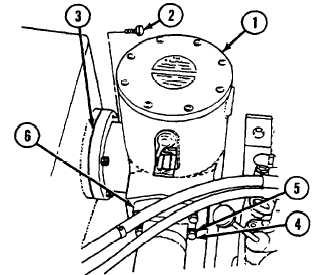

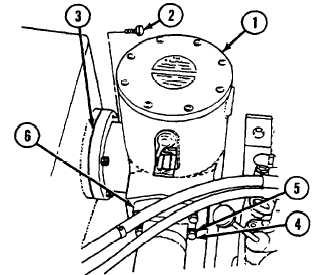

Place suitable container under filter

housing prior to removal to catch any

hydraulic oil that drains.

1

Remove four screws (2) and preformed packings

(3).

2

Remove four screws (4), four lockwashers (5), and

two flanges (6) from filter element assembly (1).

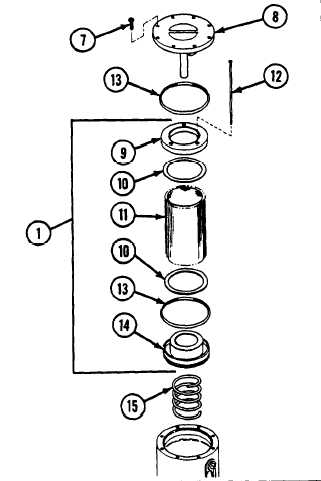

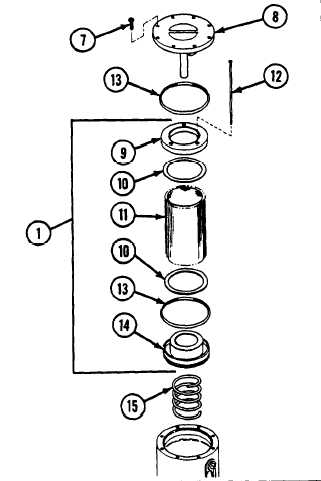

b. DISASSEMBLY

1

Remove eight screws (7) and cover (8) with filter

element assembly (1).

2

Remove filter retainer (9), two preformed packings

(10), and filter element (11) by removing three

screws (12) from cover (8).

3

Remove two gaskets (13) from cover (14).

4

Remove spring (15) from filter element assembly

(1).

c. ASSEMBLY

Dry-cleaning solvent used to clean parts

is potentially dangerous to personnel

and property. Do not use near open

flame or excessive heat. Flashpoint of

solvent is 138 degrees (°) Fahrenheit (F)

(59” Celsius [C] ).

Particles blown by compressed air can

be dangerous. Be certain to direct air

stream away from user and other

personnel in area. Compressed air used

for cleaning will not exceed 30 pounds

per square inch (207 kilopascals). Use

only with effective chip-guarding and

personal protective equipment (goggles,

shield, and gloves).

12-32

Change 1