SECTION I: WHEELS AND TRACKS

TM 9-2350-256-20

3

Install and block roadwheel arm (see paragraph

8-3).

4

Install torsion bar (6) using adapter and puller as

follows:

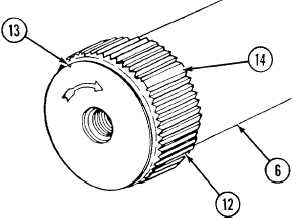

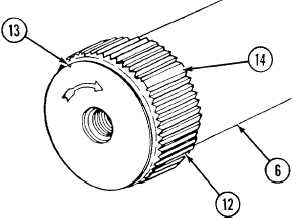

Coat serration (12) on both ends of torsion bar with

GAA grease (see Appendix J). Screw adapter into

tapped holes in end of torsion bar. Screw puller

into tapped hole in adapter. Hold torsion bar so

that V-notch (13) cut into chamfer on outer end is

at top. Slide torsion bar in and rotate until blank

serration (14) in inner end of torsion bar (opposite

V-notch) aligns with blank serration in torsion bar

anchor (10). Push torsion bar in far enough to

engage torsion bar anchor. Turn roadwheel arm

(3) in direction of arrow on torsion bar until blank

serration (adjacent to V-groove) in outer end of

torsion bar aligns with blank serration in arm

(opposite V-groove in arm). Push bar in as far as it

will go. Pack cavity in roadwheel arm with grease

(see Appendix J).

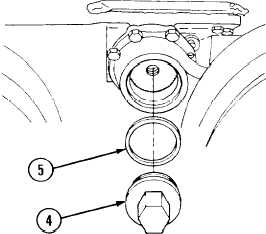

5

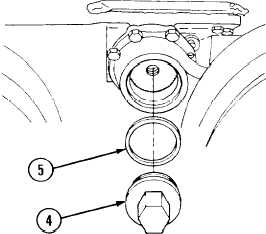

Install torsion bar end plug (4) and new gasket (5)

using wrench plug.

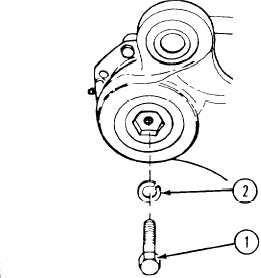

6

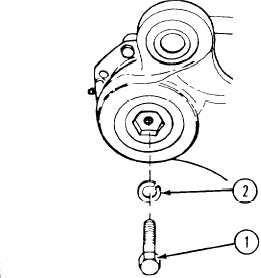

Install screw (1) and new lockwasher (2). Torque

screw to 75-100 lb-ft (102-136 N•m).

NOTE

Follow-on maintenance: •Connect shock

absorber (see

paragraph 8-12)

•Connect idler link (see

paragraph 8-8)

•Install roadwheel (see

paragraph 8-1)

Change 1

8-5