TM 9--2350--292--20--1

0095 00--3

MAIN WINCH LEVEL WINDER FAILS TO OPERATE -- CONTINUED

0095 00

G

Is pressure at port V1 within 60 psi of pressure at

supply port P and is pressure at port V2 60 psi or less

when level winder cylinder is retracting and is pressure

at port V2 within 60 psi of pressure at supply port P and

is pressure at port V1 60 psi or less when level winder

cylinder is extending?

CONTINUED FROM STEP F

no

yes

CONTINUED ON NEXT PAGE

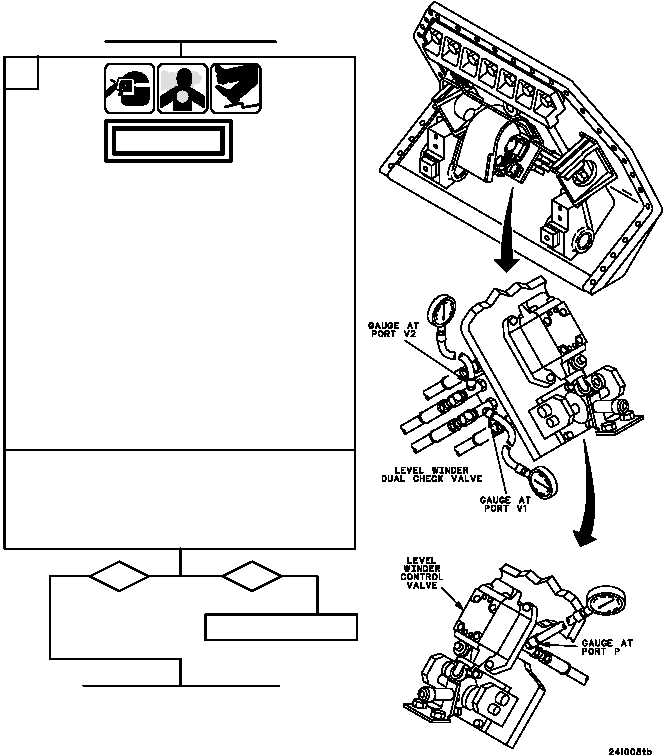

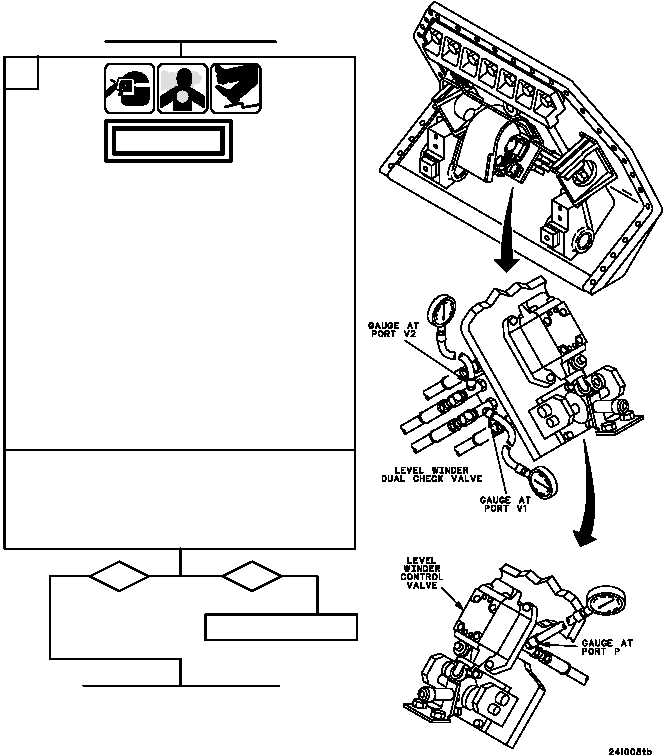

1. Install 0--5000 psi dial pressure gauge with

1/4--inch tee between attaching hose and port

V1 on level winder dual check valve.

2. Install 0--5000 psi dial pressure gauge with

1/4--inch tee between attaching hose and port

V2 on level winder check valve.

3. Install 0--5000 psi dial pressure gauge with

1/4--inch tee between pressure hose and port P

of level winder control valve.

4. Install ground hop kit (WP 0498 00).

5. Start main engine and energize main hydraulic

system (TM 9--2350--292--10).

6. Payin and payout main winch enough for

control valve plunger roller to ride up and down

the cam slope only.

7. Read gauges during cylinder extraction and

extension. Record readings.

8. Shut down hydraulics and engine

(TM 9--2350--292--10).

Go to Step K.

WARNING