TM 9--2350--292--20--2

0499 00--5

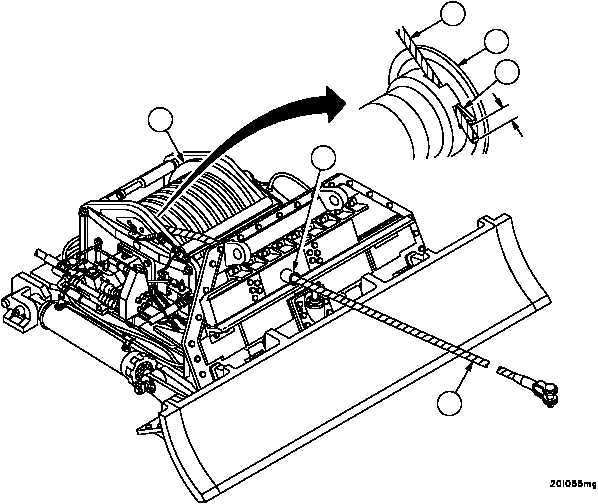

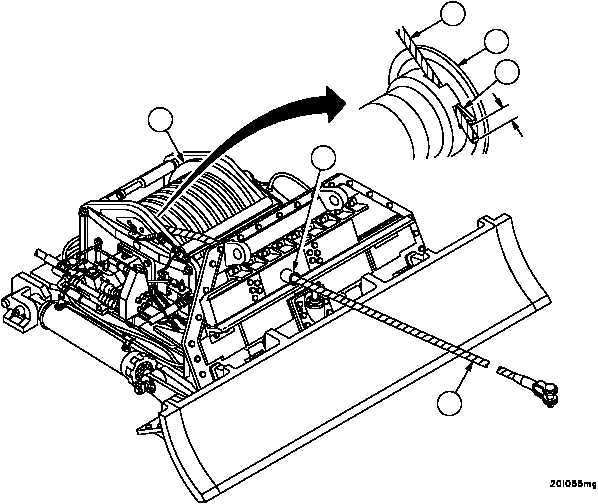

MAIN WINCH WIRE ROPE ASSEMBLY REPLACEMENT -- CONTINUED

0499 00

Installation -- Continued

6. Seat wedge (6) and wire rope (7) in winch drum (1) by driving wedge (6) approximately 2.0 inches (50.8 mm) into

hole of winch drum (1) using brass drift and hammer while wire rope (7) is being pulled through trumpet (8) by

crew member.

CAUTION

Do not use excessive force when tapping wire rope into

drum. Failure to comply may cause wire rope end to sep-

arate.

7. Tap end of wire rope (7) as necessary to maintain approximately 1.0 inch (25.4 mm) in distance between end of

wedge (6) and end of wire rope (7).

Figure 261

1

7

7

6

1

8

1.0” (25.4 mm)