SECTION V: CONTROLS AND LINKAGES

TM 9-2350-256-20

34

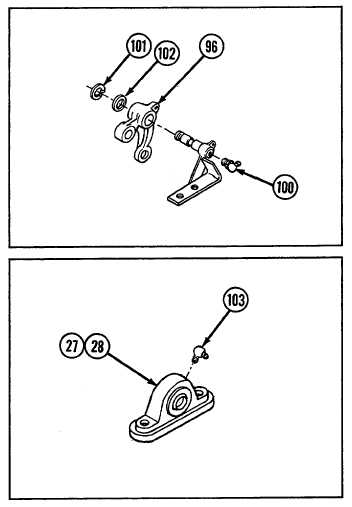

Remove lubrication fitting (100), retaining ring

(101), flat washer (102), and bell crank assembly (96).

b.

DISASSEMBLY

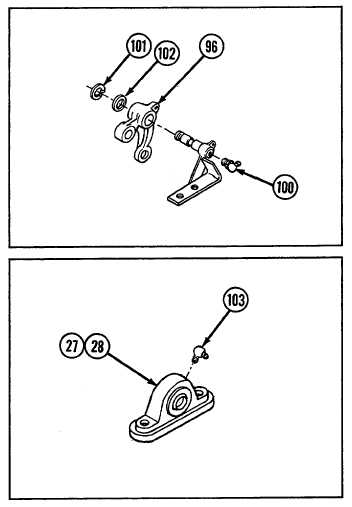

Remove lubrication fitting (103) from bearing units (27 and

28).

c.

CLEANING

WARNING

Particles blown by compressed air can be

dangerous. Be certain to direct airstream away

from yourself and other personnel in the area.

Compressed air used for cleaning will not exceed

30 psi (207 kPa). Use only with effective chip-

guarding and personal protective equipment

(goggles/shield and gloves).

Clean rubber parts in mild soap solution. Rinse in clean

water and dry with compressed air.

d.

INSPECTION

1

Inspect all parts for cracks and distortions.

2

Inspect connecting and pivot parts for excessive

wear.

3

Inspect bearings for damage.

4

Inspect threaded parts for cross threading and

nicks.

5

Inspect rubber parts for cracks and hardening.

e.

REPAIR

1

Straighten any rods which are bowed.

2

Replace any badly worn clevis rod ends or pins.

3

Repair damaged threads with thread restoring file where possible, or replace defective threaded parts.

4

Replace defective rubber parts.

f.

ASSEMBLY

Install lubrication fitting (103) to bearing units (27 and 28).

9-177